SignTorch

Artist

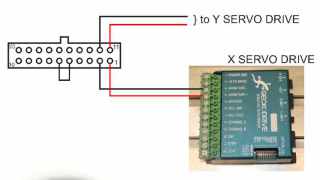

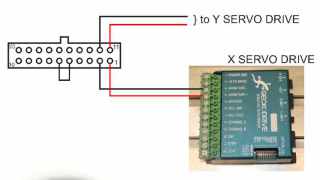

With everything turned off, wire the servo motor power wires to the servo drive armature outputs.

On each servo drive, turn the tuning trim pots fully counterclockwise. (per the manual)

My X trim pots are set like this

My Y trim pots are like this

Start by turning your trim pots almost, but not quite, the same amount as shown above. Over-tuning, turning the trim pots more than necessary, is to be avoided because the motor kind of goes crazy. We cannot really tune the trim pots at this time with the belts off.

Start Mach3, turn power on, hit reset in Mach3, set the feedrate to 10 IPM, you can enter F10 in the gcode input box.

Press the reset button on the X servo drive. The IN POS light should come on and stay on. The motor may hum, or oscillate a little when idle, that is normal.

The WARN light should not blink, and the motor should be holding its position.

If it moves, goes crazy, or the WARN light blinks constantly, you can try reducing tuning ever so slightly to get it to settle down.

Now we should be able to jog each motor back and forth and make sure the right axis rotates in the right direction with the arrow keys.

Try referencing each axis and make sure it runs in the right direction and trip the limit to make sure it stops.

Now, we can power down and put the belts back on.

Always turn Mach3 on first, then power the machine, then hit reset in Mach3, then press the reset button on each servo.

Try jogging each axis at 10 IPM. Try referencing home on each axis. Then try gcode G1x10. It should move 10 inches right. Try gcode G1X0 it should go back to zero. Try that on the Y. Then try G0X10 and G0X0. To see how it traverses.

As for fine tuning, it doesn't accomplish anything to crank up the tuning as far as possible, I just try to find a sweet spot where it idles quietest, and that seems to work good. It doesn't seem necessary to tune with an oscilloscope.

Congratulations, you now have a high performance servo driven X/Y axis to work with.

On each servo drive, turn the tuning trim pots fully counterclockwise. (per the manual)

My X trim pots are set like this

My Y trim pots are like this

Start by turning your trim pots almost, but not quite, the same amount as shown above. Over-tuning, turning the trim pots more than necessary, is to be avoided because the motor kind of goes crazy. We cannot really tune the trim pots at this time with the belts off.

Start Mach3, turn power on, hit reset in Mach3, set the feedrate to 10 IPM, you can enter F10 in the gcode input box.

Press the reset button on the X servo drive. The IN POS light should come on and stay on. The motor may hum, or oscillate a little when idle, that is normal.

The WARN light should not blink, and the motor should be holding its position.

If it moves, goes crazy, or the WARN light blinks constantly, you can try reducing tuning ever so slightly to get it to settle down.

Now we should be able to jog each motor back and forth and make sure the right axis rotates in the right direction with the arrow keys.

Try referencing each axis and make sure it runs in the right direction and trip the limit to make sure it stops.

Now, we can power down and put the belts back on.

Always turn Mach3 on first, then power the machine, then hit reset in Mach3, then press the reset button on each servo.

Try jogging each axis at 10 IPM. Try referencing home on each axis. Then try gcode G1x10. It should move 10 inches right. Try gcode G1X0 it should go back to zero. Try that on the Y. Then try G0X10 and G0X0. To see how it traverses.

As for fine tuning, it doesn't accomplish anything to crank up the tuning as far as possible, I just try to find a sweet spot where it idles quietest, and that seems to work good. It doesn't seem necessary to tune with an oscilloscope.

Congratulations, you now have a high performance servo driven X/Y axis to work with.