SignTorch

Artist

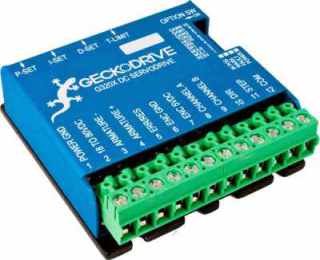

I used ordinary gecko servo drives - https://www.geckodrive.com/products/g320x-digital-servo-drive - two required

The servo drive controls high power voltage going to the motor, based on step and direction signals from the BOB, much like a stepper motor.

Unlike a stepper, servos rotate continuously and have an optical encoder to track rotation, which the servo drive monitors to move a certain distance per step, and to hold position when idle.

One problem with a servo is, when it gets a step signal, it basically takes off at full speed, and depends on the encoder signal to tell it when to stop when the step is complete. If the encoder isn't working, the motor doesn't stop, it runs away at full speed. So we have to be careful during hookup and testing, be ready to kill the power if that happens, and make sure the encoder power source and wiring is reliable.

The encoders are high resolution with 500 lines which produces 2,000 pulses per revolution. Which makes for a high frequency signal at high speed, so the encoder wiring must be shielded and no longer than necessary.

Servos outperform steppers because they are free spinning DC motors and can turn at several thousand RPM with no loss of power at low or high speed.

Servo drives have tuning parameters to control how abruptly they attempt to correct differences between the actual and commanded position.

Getting a servo drive hooked up, tested, tuned, and working is a careful, methodical, step by step process which must be worked through. Unlike a stepper you can't just hook up an arbitrary motor to an arbitrary drive and expect it to work right off the bat.

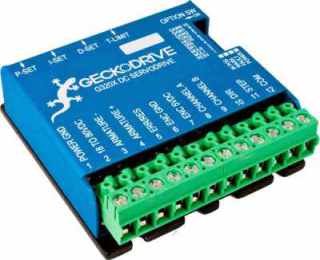

The servo drive controls high power voltage going to the motor, based on step and direction signals from the BOB, much like a stepper motor.

Unlike a stepper, servos rotate continuously and have an optical encoder to track rotation, which the servo drive monitors to move a certain distance per step, and to hold position when idle.

One problem with a servo is, when it gets a step signal, it basically takes off at full speed, and depends on the encoder signal to tell it when to stop when the step is complete. If the encoder isn't working, the motor doesn't stop, it runs away at full speed. So we have to be careful during hookup and testing, be ready to kill the power if that happens, and make sure the encoder power source and wiring is reliable.

The encoders are high resolution with 500 lines which produces 2,000 pulses per revolution. Which makes for a high frequency signal at high speed, so the encoder wiring must be shielded and no longer than necessary.

Servos outperform steppers because they are free spinning DC motors and can turn at several thousand RPM with no loss of power at low or high speed.

Servo drives have tuning parameters to control how abruptly they attempt to correct differences between the actual and commanded position.

Getting a servo drive hooked up, tested, tuned, and working is a careful, methodical, step by step process which must be worked through. Unlike a stepper you can't just hook up an arbitrary motor to an arbitrary drive and expect it to work right off the bat.